Closing the gap between current and potential performance

During our years in the field, we have witnessed the same pattern over and over again. When mining operations see shifts where they reach little to no production, the knee jerk reaction is to invest in new equipment, hoping this will help them boost production.

What this logic fails to recognise is that operations weren’t falling behind on all shifts – in fact, they might have been thriving on some shifts but falling way behind on others, with little to no clue as to why this was happening.

In other words, the problem was variability.

Experience has shown that when mines see significant variability in day-to-day operations and then try to solve the issue by investing in new equipment, it’s more than likely that they will see productivity go up on the shifts where they were already succeeding, while making little improvement on the other shifts.

In other words, the new equipment will cause even more variability.

Consistency is key

Regardless of mining method and location, businesses across the board are struggling to secure the investment they need to take their operations to take next level. Mining itself has become more challenging with resources becoming more scarce and harder to mine – and that’s not even taking into account the current constraints taking their toll on the industry.

To secure investment in the current climate and to do so in an industry that’s inherently unpredictable, operations need to be able to deliver reliable performance from shift to shift. Unfortunately, operations will often see variability to such an extent that managers are unable to predict whether they’ll achieve 0% or 100% of their target.

Needless to say, this is not an attractive proposition for investors.

This is why we believe it is essential for businesses to get to the root causes of variability and to get control of their operations before investing in any new equipment or business improvement solutions. This is the only sustainable way to close the gap between current and potential performance.

Three essential steps for closing the gap

So rather than investing in new equipment when operations plateau or falter, what should the remedy be instead? In our view, there are three steps that mining operations need to take sequentially to reach their maximum potential and to deliver consistent results.

These three steps were inspired by “The Four Levels of Involvement” outlined by the late Professor David Upton of Harvard Business School in his paper Mechanisms for Building and Sustaining Operations Improvement.

Three steps for closing the gap between current and potential performance

- Get control to reduce variability.

- Optimise / improve the drivers of process performance.

- Invest capital in technology or equipment.

In order to achieve sustainable gains in productivity, it is crucial that these steps are taken sequentially. Where most businesses go wrong is in skipping the first two steps altogether. This means they are putting the cart before the horse and setting up any further investments on a shaky foundation.

Creating a solid foundation

So how do you do that – get control of your operations to reduce variability? Conventionally, mining operations have tried to do this by hiring expensive consultants who would set up elaborate spreadsheets and white boards that were meant to manage work in complex mining operations.

Well, all we can say is “been there, done that.” Back in the day, we too started out as consultants. It didn’t take long for us to discover that these disjointed manual systems simply weren’t up to the challenge. Pretty much anyone in the industry will agree that spreadsheets and white boards are hard for people to use which also makes them unsustainable in managing day-to-day work.

Since launching our software over a decade ago, Commit Works has helped operation across different locations and mining methods complete step one in a very short amount of time. Looking at the data, operations across the board had reduced variability and substantially increased their average performance after implementing our software. And here’s the real game changer: in all cases, the number of shifts where little to no production was achieved has been significantly reduced. In a very short amount of time, our software had solved the problem of variability.

The importance of an operational backbone

To get control over day-to-day work, operations need to sit on a solid foundation. At its best, a well-designed and properly implemented software functions as an operational backbone which drives continuous improvement.

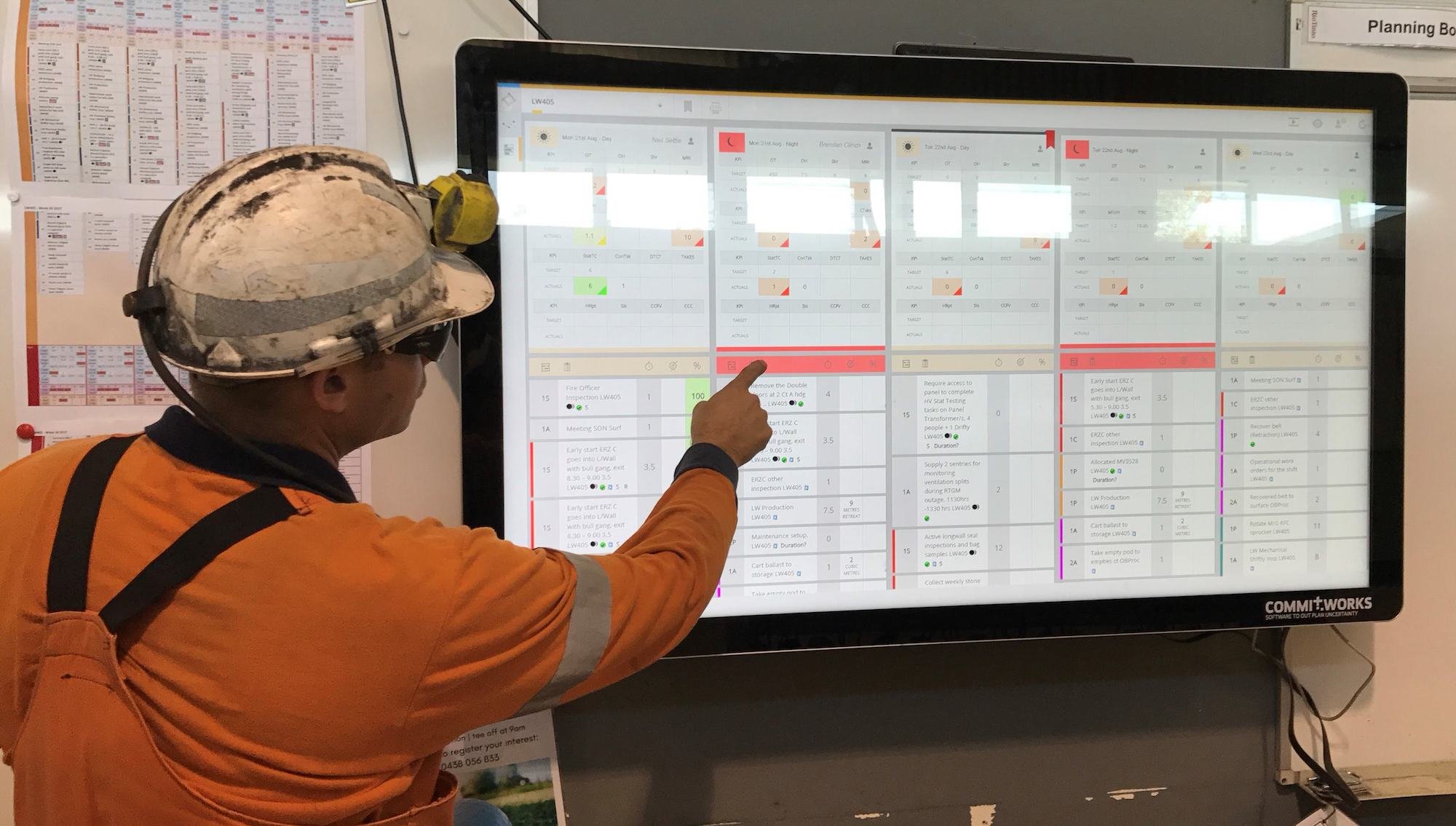

Our software allows managers and supervisors to track the work taking place on site against the shift plan in real time. In a complex mining environment, it’s inevitable that things change as the work happens: perhaps key equipment needs maintenance or the necessary people are not available to complete a task. With our software, these changes are visible to everyone on site. This allows for immediate course correction to protect the plan. It also makes any repetitive patterns or larger issues visible.

In other words, our software allows operations to make countless small improvements to improve their productivity and to reduce variability. Beyond that, operations can detect any larger issues causing delays and downtime and address these before making any further investments.

Driving productivity in a sustainable way

Establishing an operational backbone empowers teams to reduce variability and to improve their average performance, allowing mines to achieve significant gains without spending any capital. This stable operational foundation means mines will be able to attract potential investors with reliable results and sustained productivity. Once further investments are made – whether they be new equipment or business improvement initiatives – they will be sitting on a stable operational foundation, which means they will be able to improve overall productivity in a sustainable way.

After all, creating a solid and stable foundation should be a prerequisite for any type of investment. When you first have control of your operations and then invest in new technology or equipment, then and only then will your operations be able to reach their full potential and move to the next level.

We have seen The Three Steps deliver significant results time and time again with our clients. Typically, our clients have seen a rapid and sustainable lift in performance by more than 10%.